Amar has been a pioneer, largest manufacturer, and exporter of continuous flow reactors in India since many years. Amar Flow reactors are used by various industries like fine & speciality chemicals, bulk drugs (API) pharmaceuticals, dyes, intermediates, paints, agrochemicals, etc. to convert their batch chemistries to continuous flow.

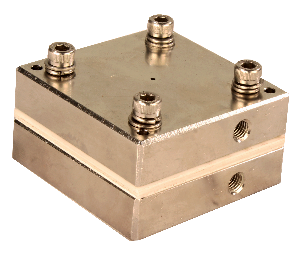

Amar Equipment are principals for LTF flow chemistry reactor chips in India. LTF reactor chips are specialized reactor chips for efficient mixing of chemicals and plug flow channels which can be used to carry out the corrosive reaction effectively.

Considering your requirement, we can customize the number of inlets, type of mixing elements required and develop a suitable chip set for your lab scale flow needs. LTF offers a wide range of chip sets on a standard basis and equally competent for your microfluidic needs.

| Model | Mr. Lab | ||||

|---|---|---|---|---|---|

| Pressure Tested ( bar) | 15 | ||||

| Advantages | Easy to use & Space saving | ||||

| Models | LTF MX | LTF MS | LTF V | LTF VS | |

| Volume ( ml ) | 0.2 | 0.2 | 1.7 | 1.1 | |

| Material of Construction | Borofloat 33 | ||||

| Dimension ( mm ) | 115 x 60 x 6 ± 0.5 | ||||

| Channel size ( mm ) | 1 | ||||

| Inclusive Connection | Inclusive Connection Bar 1⁄4” unf 28 | ||||

| Model | Mr. XXL |

|---|---|

| Process | From Batch to Continuous |

| Integrated Layers | For mixing / reaction / heat transfer |

| Pressure Tested ( bar) | 15 |

| Connections | Connecting via 1⁄4” UNF 28 fittings & 1⁄4” Swagelok |

| Advantages | Easy to Use & Space Saving |

| Dimension ( mm ) | 150 x 150 x 14 |

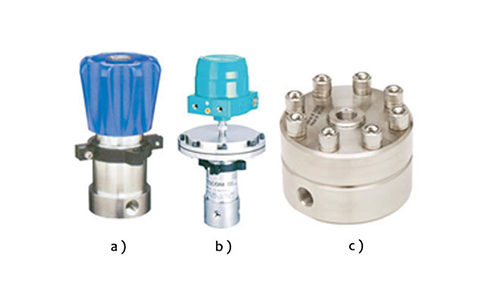

Apart from our standard specifications we also provide additional value-added optional accessories to enhance the versatility and functionality of the equipment for various applications. Some of the components that we provide as a part of our flow reactor systems :

It is SS316 regulator mounted on the vent line of the reactor &is used for maintaining constant pressure inside the reactor up to 350bar. The pressure is maintained by releasing the excess pressure into the atmosphere.

Optional

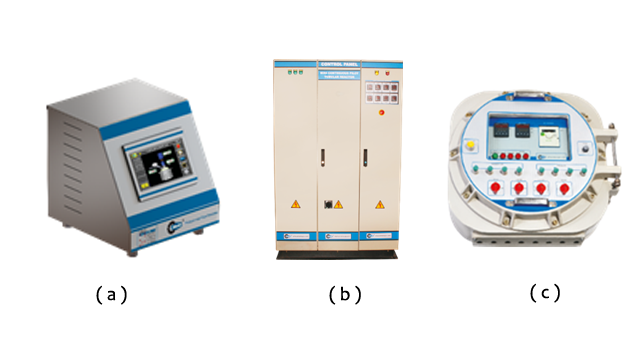

Control Panel consists of programmable PID temperature controller cum indicator with temperature alarm system (settable), safety alarm & heater trip system for malfunctioning of controller/sensor/ temperature rise beyond set limit. Digital pressure indicator/ controller, gas/liquid flow indicator, totalizer, heater, level, pH etc. Indicators are provided additionally on same common control panel depending on the optional accessories are selected.

Optional :

It consists of SS316 pressure sensor (transmitter) & digital pressure indicator/ controller (mounted on common control panel) with pressure alarm.

This unit is used to separate plug flow of two immiscible liquids used in biphasic reaction or two phases of an extraction flow.

MOC: ETFE, PFA & PTFE, pressure @ 300 psi.

This system is used to charge liquid at a desired rate from as low as 1ml/hr, is under pressurized condition.

MFM can be used to measure accurate mass flow rate of gas (in gm/hr or LPH) & totalized quantity of mass/volume (in gm/ltr) charged in the reactor at any point. Mass flow controller (MFC) is used to charge the set flow rate of gas into the reactor at high pressures up to 100bar. The same MFM/MFC comes with high pressure flexible hose, inlet filter with digital gas flow indicator.

Note : All accessories may not be applicable for the selected model. For more details Contact US.